Filament Winding Structure 碳纤维编织结构

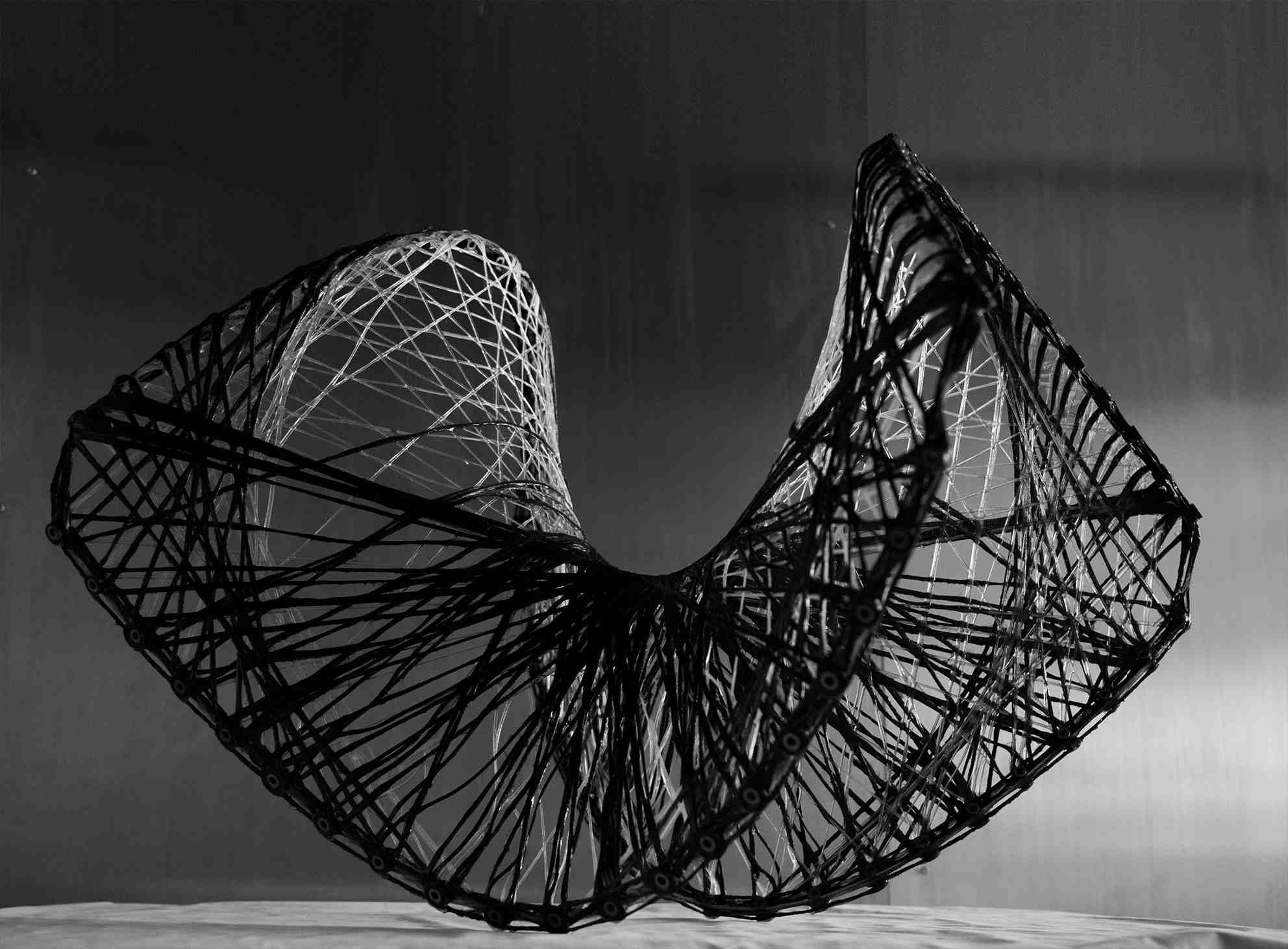

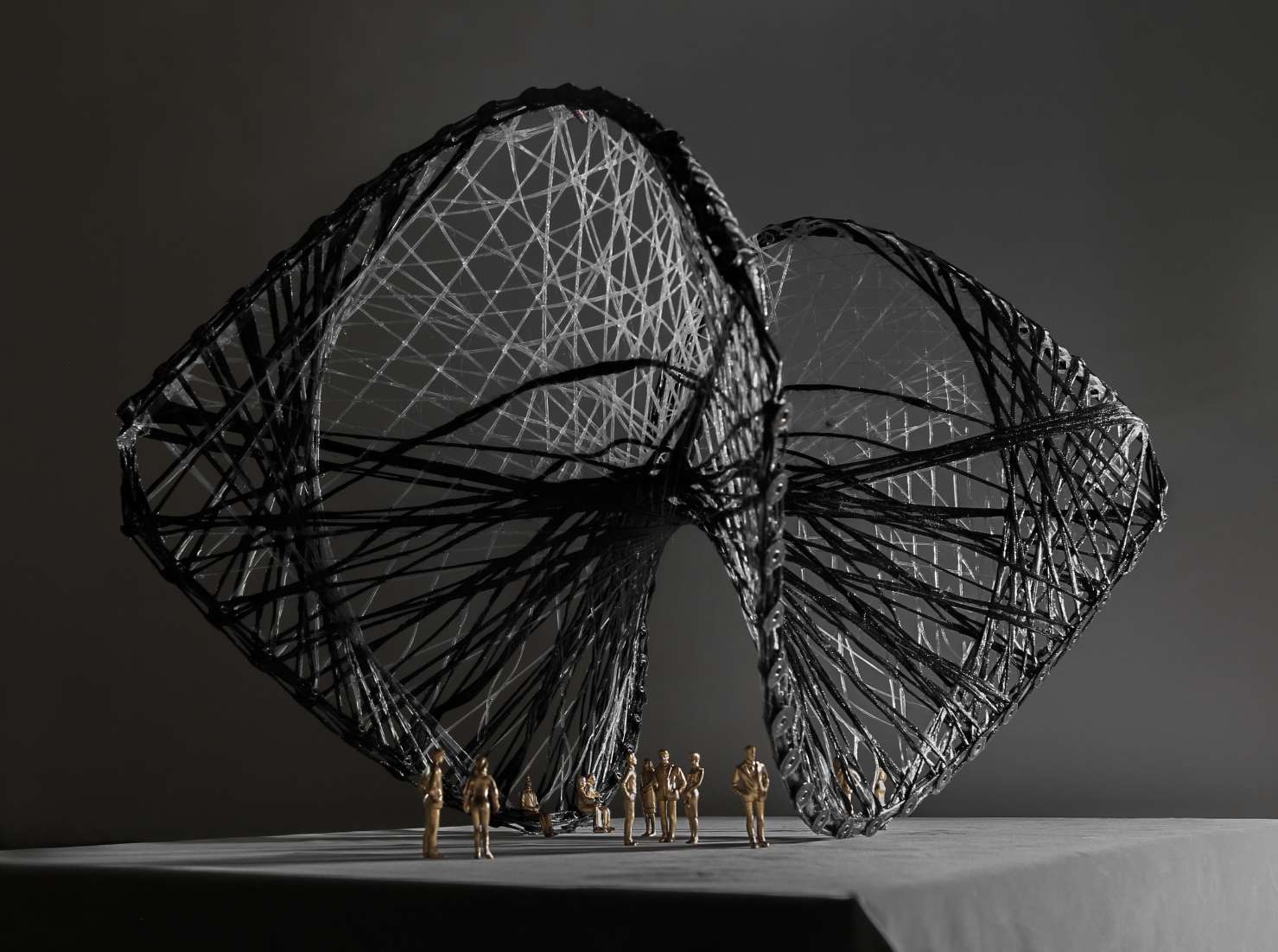

This is a collaboration between topology and architecture, a manifesto for endless possibilities for space design with filament winding structure.

Like the butterfIy effect, a little fIap of weaving points will create continuous topological variation that engenders infinite spatial experiences. These topologies can be transformed into different scales for human use and mudular systems accordingly.

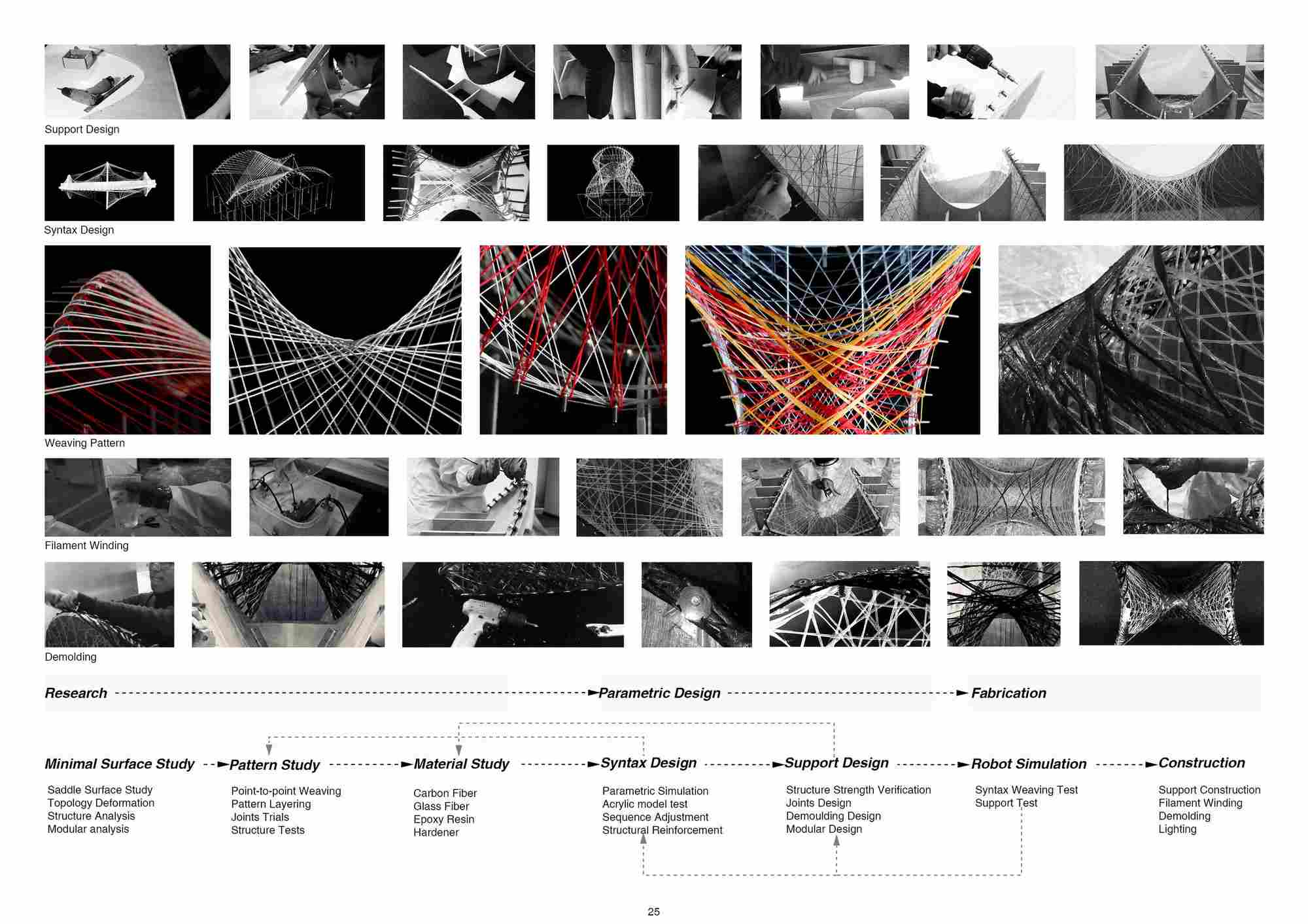

Inspired by ICD's experiments on filament winding structure design and the studio "Material Performance" in GSD, the final design is achieved by simulating woven carbon fiber and glass fiber with a robotic arm, so that the weave pattern means not only a decoration, but a space with internal structural characteristics. Throughout the process, we constantly adjust the fiber weaving sequence and perform stress analysis of mechanics to obtain the most aesthetic form and the design prototype that best fits in the structural logic.

这是拓扑学与建筑的合作,展现了通过纤维缠绕结构实现空间设计的无限可能性。就像蝴蝶效应一样,一点微小的编织点变化将产生持续的拓扑变化,进而创造出无穷的空间体验。这些拓扑结构可以根据不同的尺度和模块系统转化为适合人类使用的空间。

灵感来源于ICD在纤维缠绕结构设计上的实验,以及GSD的“材料表现”工作室,最终设计通过模拟碳纤维和玻璃纤维的编织方式,由机器人臂完成。编织的图案不仅仅是装饰,而是具有内部结构特性的空间。在整个过程中,我们不断调整纤维编织的顺序,并进行机械应力分析,以获得最具美感的形式和最符合结构逻辑的设计原型。

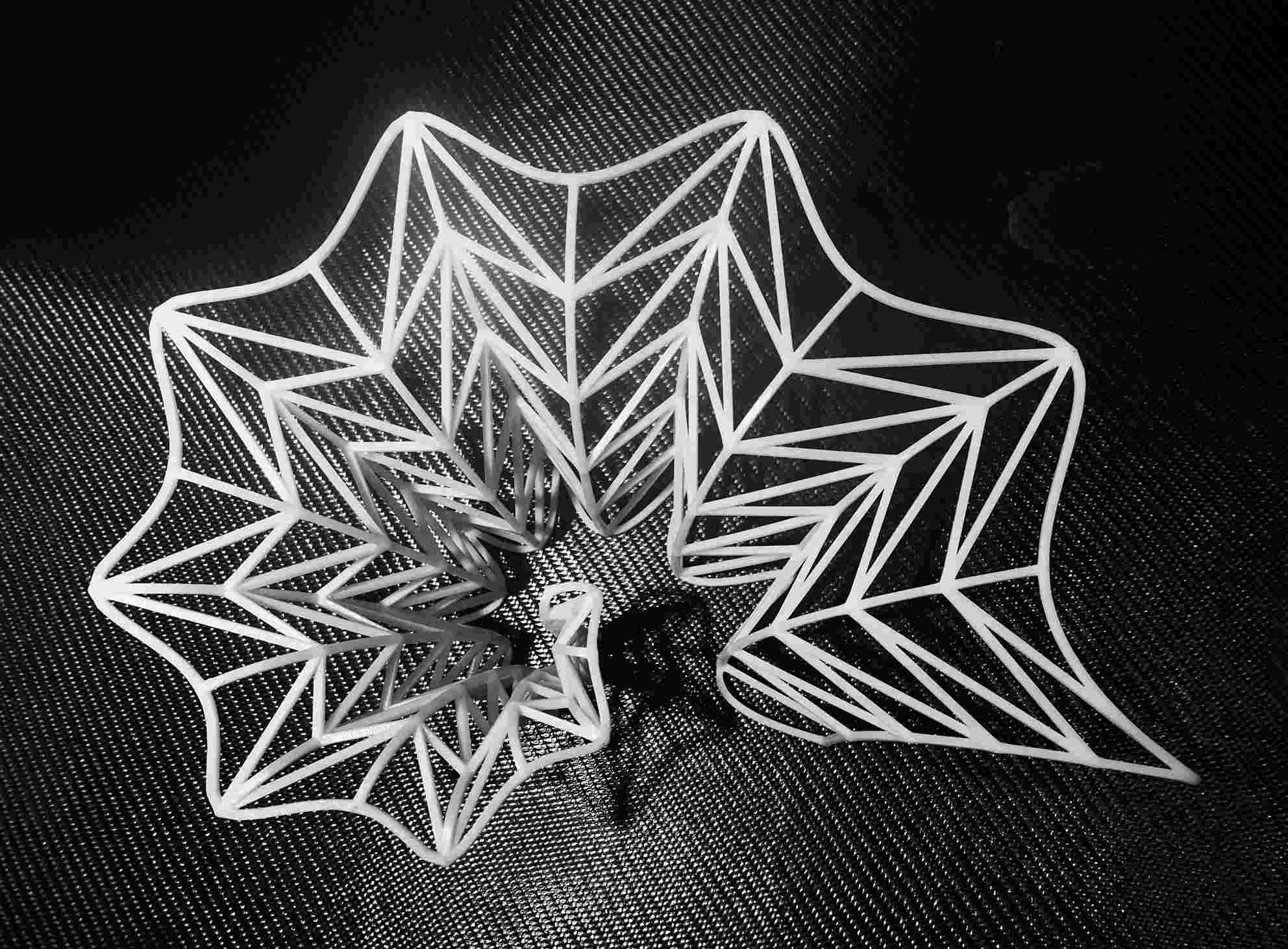

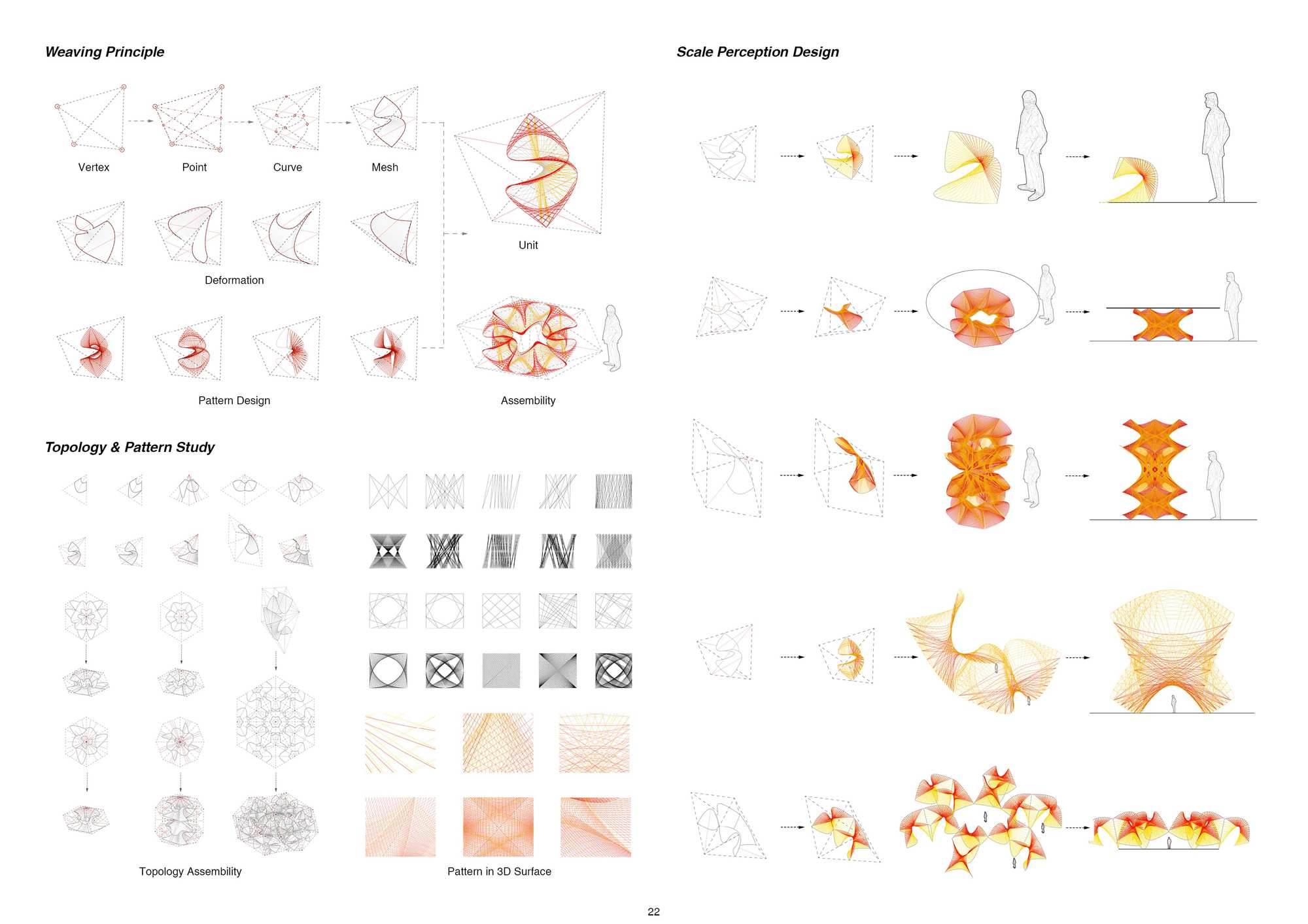

Weaving principle 编织设计原理

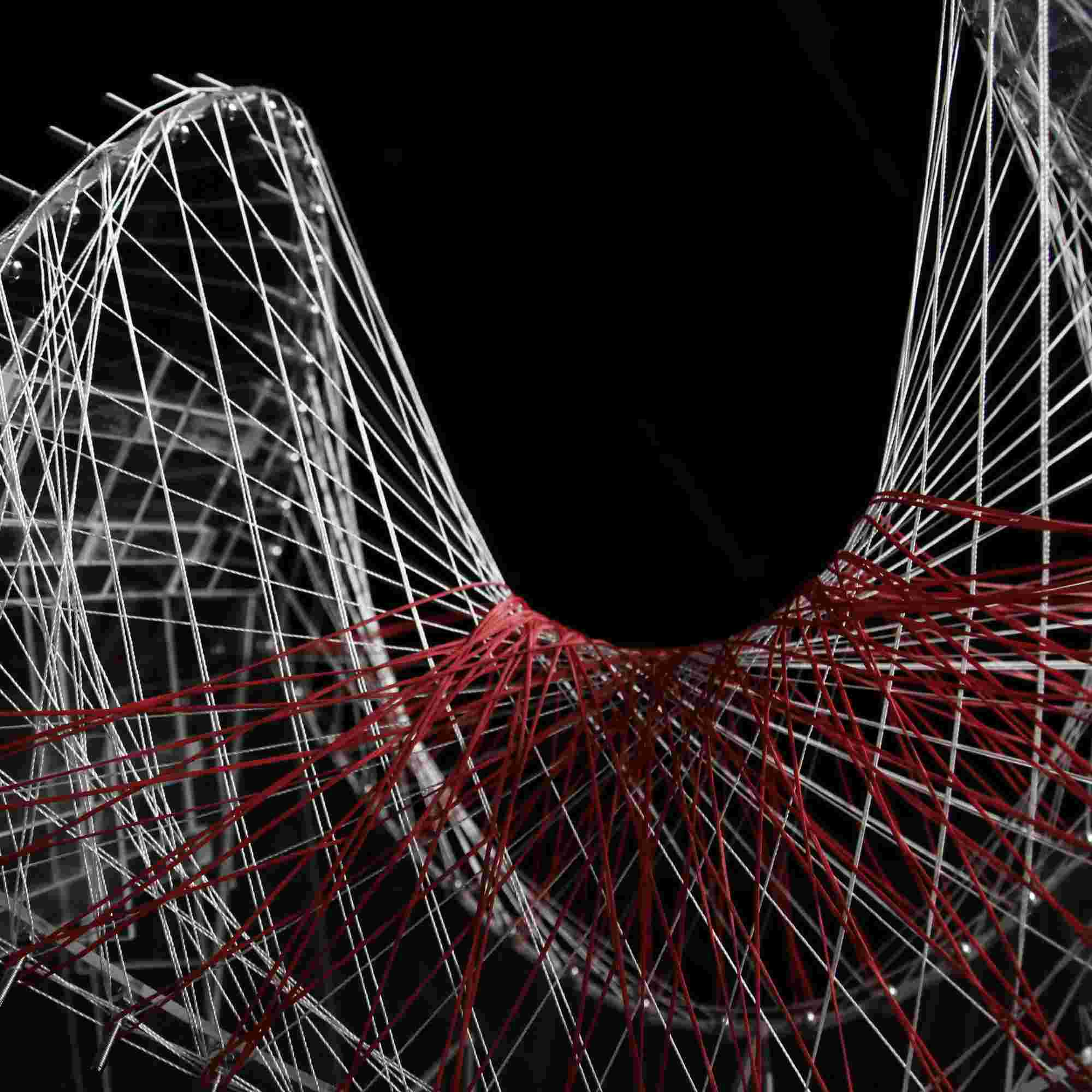

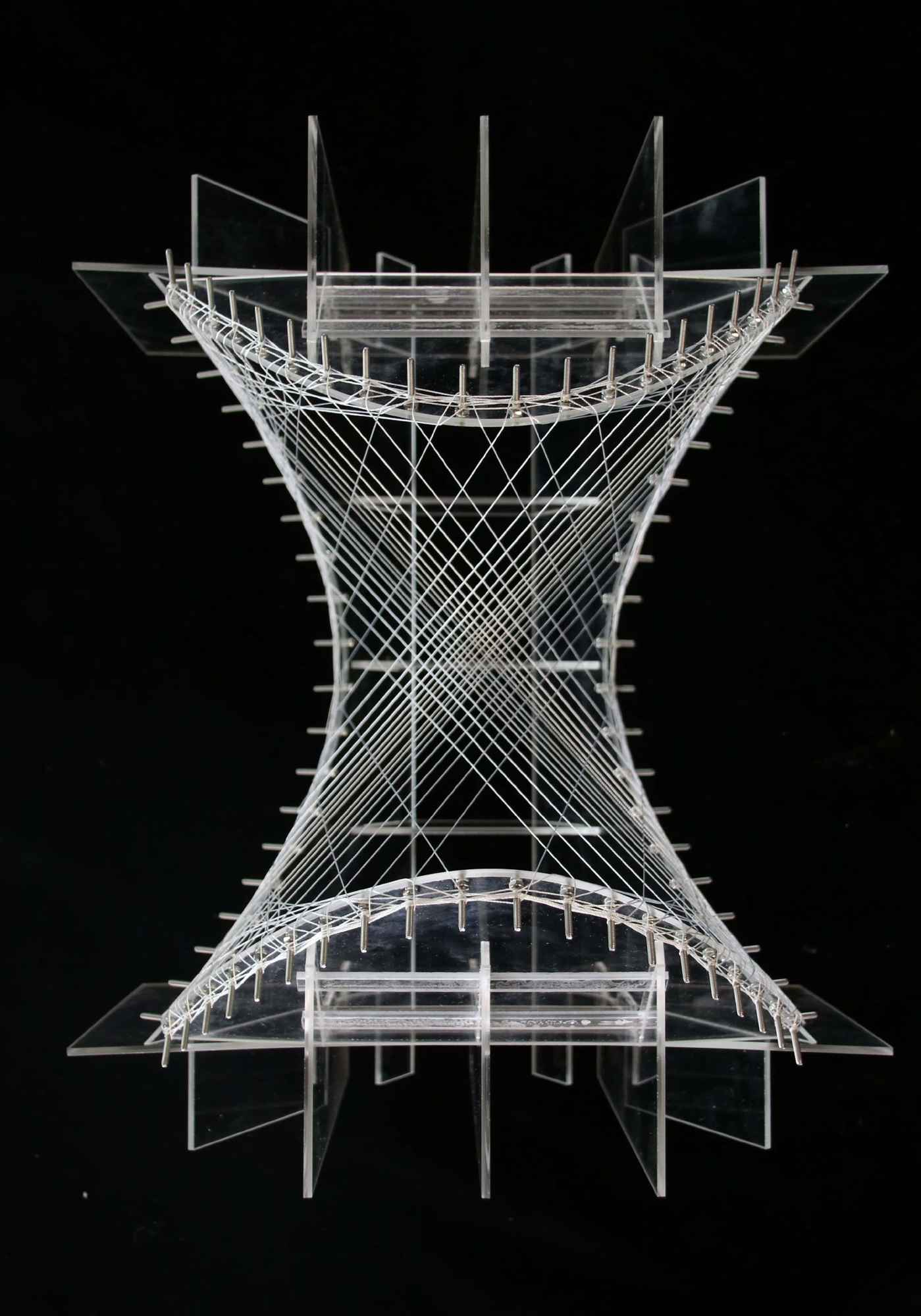

Through the study of woven textures, we can create a variety of intricate weaving patterns by adjusting the weaving sequence and the arrangement of connection points. Based on small curved surfaces and saddle shapes, this weaving language is applied to curved forms. Additionally, by combining prototypes, these woven structures can be transformed into various functional objects such as small seating, round tables, tall columns, exhibition spaces, and more, demonstrating great versatility and adaptability. 通过对编织纹理的研究,我们可以通过调整编织顺序和连接点的排列方式,创造出丰富多变的编织语言。基于极小曲面和鞍形面,我们将这种编织语言应用于曲面造型上。同时,通过原型的组合,这些编织结构可以转变为不同的功能性物件,如小型座椅、圆桌、高柱、展厅等,展现出极大的变化和适应性。

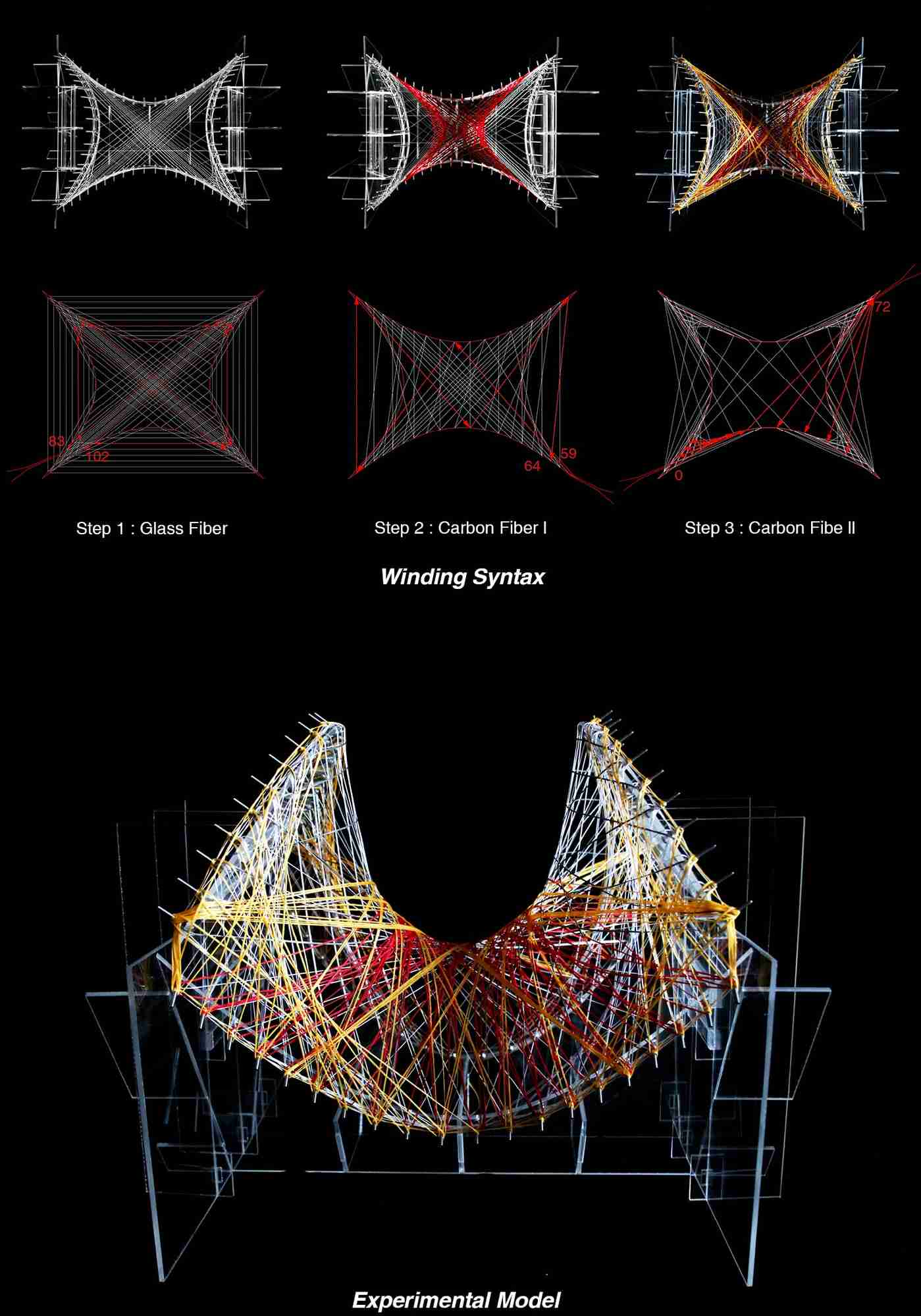

Multi-layer Weaving 多层编织

We conducted a three-layer weaving experiment on a scaled-down acrylic mold model to explore the performance of woven structures across different layers. First, fiberglass was used to shape the entire surface into a basic form, providing a flexible yet stable surface structure. Next, carbon fiber was introduced to reinforce the central area, enhancing the surface's load-bearing capacity and stability. Finally, the four corners were specifically strengthened to ensure the overall structural integrity and support. This layered reinforcement approach allowed us to achieve a structure that is both lightweight and robust, laying a strong foundation for future larger-scale designs. 在亚克力模具的缩尺模型上,我们进行了三层编织的尝试,探索编织结构在不同层次上的表现。首先,使用玻璃纤维将整个曲面塑造为一个基础形态,提供了柔韧且稳定的表面结构。接着,我们引入碳纤维进行中部的加固,增强了曲面的承载力和稳定性。最后,针对四个角部进行了重点加固,确保了整体结构的稳固性和支撑力。通过这样的分层加固,我们实现了既轻盈又坚固的结构效果,为后续更大尺度的设计提供了有力支持。

Robotic Fabrication 机械臂加工

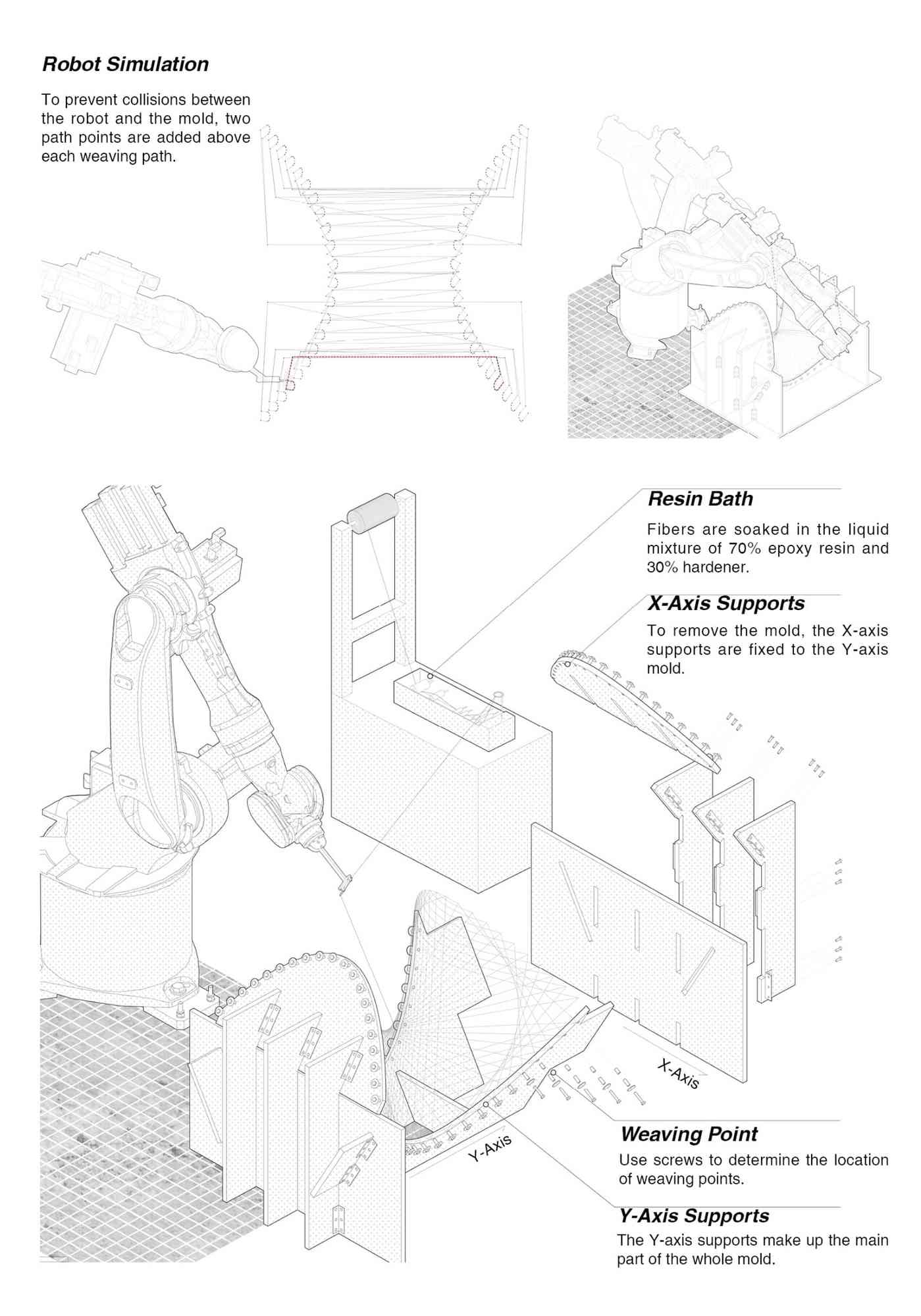

For the support design, we constructed a mold using wooden panels and incorporated removable bolts at the endpoints of the weave to ensure that the completed structure could be detached from the mold from the inside. In the anticipated construction process, we designed a workflow for the robotic arm, calculating the avoidance paths during the weaving process and the specialized design for the robotic arm's end effector to ensure precise and efficient weaving. 支座设计部分我们用木板搭建出模具,在编织的各端点设置可拆卸的螺栓,确保整体编织完成可从内部脱开模具部分。在预期建造中,我们设计了机械臂搭建的流程,计算了编织过程中机械臂的避让路径,以及机械臂端头的特殊设计。

Module Design 模块设计

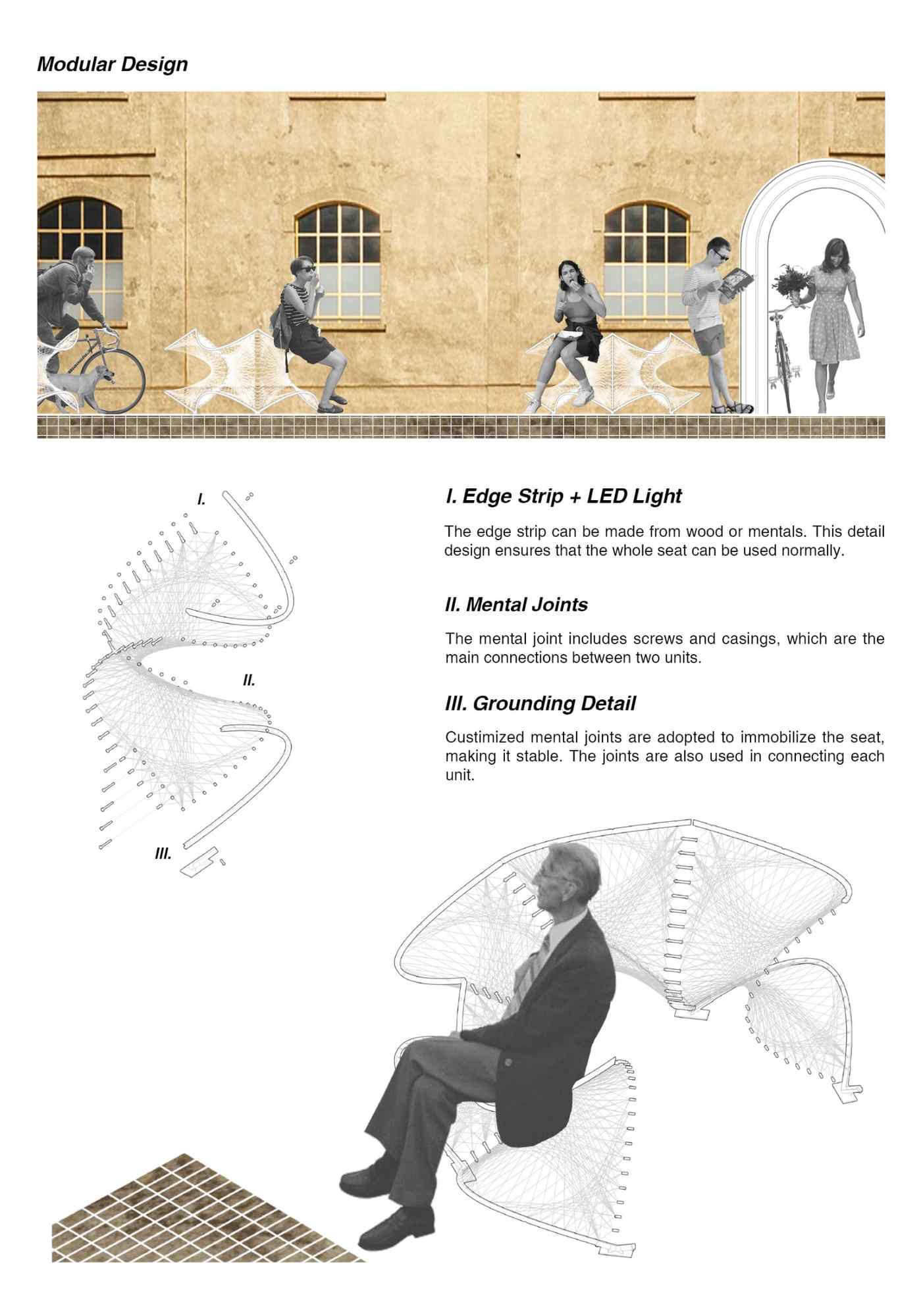

To better accommodate human scale, we incorporated more modular design details. For instance, at the edges, we seamlessly integrated LED light strips, providing soft illumination while enhancing the visual depth and aesthetic appeal. Additionally, to ensure the structural stability and adaptability, we added metal components at the connection points where the modules meet the ground. These metal connectors not only reinforced the overall support but also added a modern industrial touch, giving the space more expressive and functional qualities. 为了更好地适应人体尺度,我们在设计中加入了更多模块化细节。例如,在收边的部位,我们巧妙地嵌入了LED灯带,既提供了柔和的照明效果,又增强了视觉上的层次感和美感。同时,为了确保结构的稳固性和适应性,我们在模块的落地连接处增设了金属构件,这些金属连接件不仅强化了整体的支撑能力,还为结构增添了一种现代工业感,赋予空间更多的表现力和功能性。

Project Gallery 项目图集